| Drying Time | 10℃ | 20℃ | 30℃ |

|---|---|---|---|

| Set to touch | 6hours | 4hours | 2.5hours |

| Dry-through | 12hours | 8hours | 6hours |

| Full hardness | 7days | 5days | 3days |

| Property | Epoxy | Urethane | Surface Hardener | n-Coat |

|---|---|---|---|---|

| Component | Bisphenol base epoxy resin + Amine base hardener |

Isocyanate base resin + Polyol base hardner |

Modified silicate base | Inorganic-organic compound based on silicate |

| Work flow | Surface treatment → Undercoat → Top coat |

Surface treatment → Undercoat → Top coat |

Surface treatment → Coat →Spreading → Cleaning |

Surface treatment → Top coat |

| Membrane | YES | YES | NO | YES |

| Advantages |

• High performance of Hardness, impact resistance, abrasion resistance • High performance of Chemical, acid, salt water, solvent, oil, water resistance • Freely colored • Good adhesion to substrate • Easy maintenance |

• High performance of Hardness, impact resistance, abrasion resistance • High performance of Chemical, water resistance • High performance of Acid, impact resistance • Durability • Elasticity |

• Stimulating early curing of concrete • Controlling dust release of concrete • Reinforcing concrete surface • Preventing against entering of moisture, chemical substances • Improving durability of concrete |

• Having both functions of surface hardener and coating agent • Excellent in fire, chemical, abrasion resistance • Staining resistance, excellent chemical, salt water, solvent, acid, oil, alkali, water resistance • Water vapor permeability • Freely colored • Good adhesion to substrate • Easy maintenance |

| Disadvantages |

• Yellowing • No water vapor permeability • Poor adhesion to crystallizing polymer o non-polar polymer (PE, PP, Silicon, Acryl) • Low fire resistance |

• Lower adhesion relatively than Epoxy • Poor scratch resistance, staining resistance than Epoxy due to soft membrane • No water vapor permeability • Low fire resistance |

• Having both functions of surface hardener and coating agent • Poor staining resistance than Epoxy, Urethane • Complicated work • Expensive cost |

• Mixing at jobsite due to 2 component type |

| Epoxy | Urethane | Surface Hardener | n-Coat | |

|---|---|---|---|---|

| Adhesion | E | G | E | E |

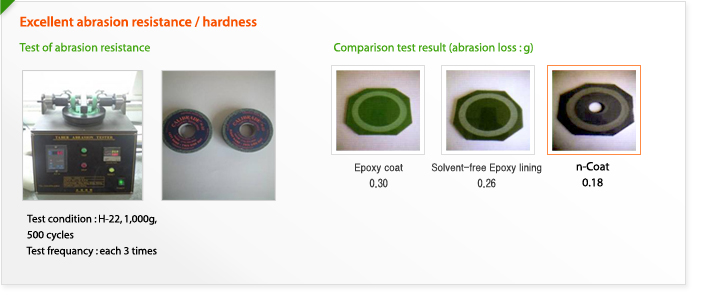

| Abrasion resistance | G | P | E | E |

| Staining resistance | G | P | G | E |

| Scratch resistance | G | P | G | G |

| Fire resistance (Firing, flame spread) | P | P | E | E |

| Appearance (Leveling, color, roller marking, glossing) |

E | G | B | E |

| Water vapor permeability | B | B | G | G |

| Chemical resistance (solvent) | E | G | P | E |

| Water resistance | G | G | B | E |

| Acid, Alkali resistance | G | G | B | E |

| Waterproofing | E | E | P | E |

| Anti-slip | P | P | E | G |

| Maintenance (cleaning, repair , durability) | G | B | B | E |

E : Excellent G : Good P : Plane B : Bad |

||||